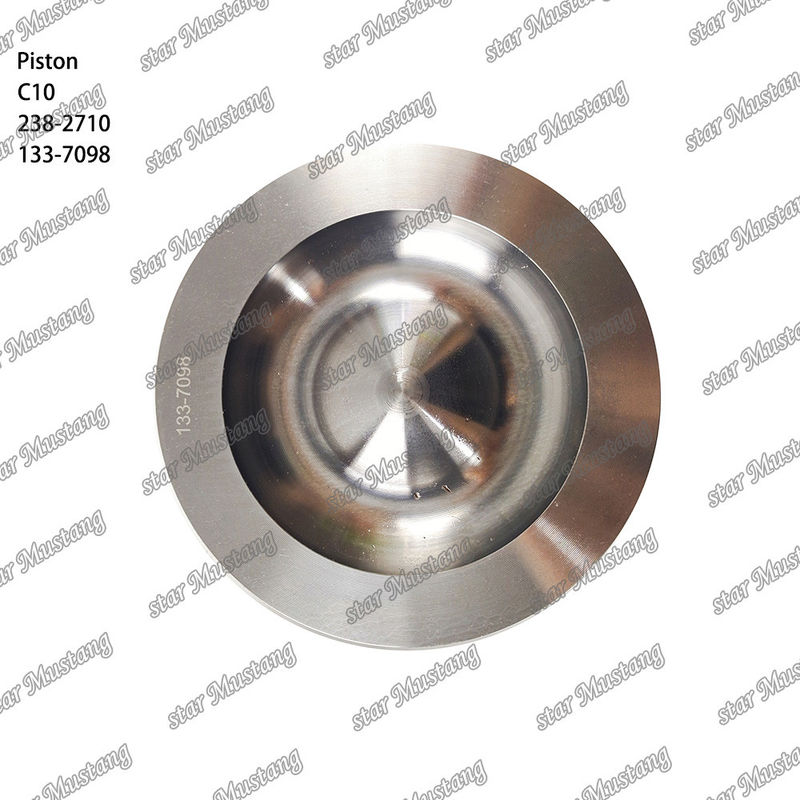

Product Description

Regarding the mechanical history of the C10 piston, the primary focus is on its evolution and development into use in diesel engines.

Design and Development Phase: Design and development of the C10 piston is typically undertaken by the engine builder or a specialist piston builder.

During the design stage, engineers will consider the diesel engine's working environment, power output requirements, emission standards and other factors to determine the material, structure and manufacturing process of the piston.

Material Selection: As materials science and engineering advance, piston materials continue to evolve.

While early pistons may have been made from cast iron or cast copper alloy, modern C10 pistons are typically made from high-strength aluminum alloy or cast iron materials to meet higher performance and durability requirements.

Manufacturing process: The manufacturing process of the piston is also continuously improved and optimized to improve the accuracy, surface quality and durability of the piston.

Modern manufacturing technologies include CNC machine tool processing, surface treatment technology, coating technology, etc., which can produce high-precision and high-performance piston products.

Performance optimization: With the continuous development of engine technology, the design of piston is also constantly optimized to improve the engine's power density, fuel economy and emission performance.

The structure of the piston, internal cooling channel design, anti-wear coating, etc. may have been improved to adapt to more stringent engineering requirements.

Application fields: C10 pistons are widely used in various diesel engines, including commercial vehicles, construction machinery, ships, generator sets and other fields.

In different application fields, pistons may have different designs and requirements to adapt to different working environments and workloads.

Overall, the mechanical history of the C10 piston reflects the development and evolution of diesel engine technology and the continual optimization and improvement of the piston as one of its key components along the way.

As a key component in diesel engines, C10 piston has some characteristics:

High-strength materials: C10 pistons are typically made from high-strength aluminum alloy or cast iron materials to withstand the workload in high-pressure and high-temperature environments.

Precision machining: The piston surface is precision machined to ensure its dimensional accuracy and surface smoothness to improve the sealing between the piston and the cylinder liner and reduce friction loss.

Optimized structure: The structure of the C10 piston has been optimized to ensure its stability and durability under high loads and high speeds, while minimizing weight and improving the engine's power-to-weight ratio.

Anti-wear coating: In order to further improve the wear resistance of the piston, a special anti-wear coating may be coated on the piston surface to reduce friction and wear between the piston and the cylinder liner, and extend the service life.

Cooling channel: For applications in high-temperature environments, the C10 piston may be designed with an internal cooling channel to control the temperature of the piston by circulating coolant to improve the heat resistance and thermal stability of the piston.

Lightweight design: In order to reduce inertia load and improve engine responsiveness, the C10 piston may adopt a lightweight design to reduce the weight of the piston by optimizing the structure and material thickness.

Corrosion Resistance: C10 piston materials and surface treatments may provide good corrosion resistance to resist chemical corrosion and oxidation that may be encountered during engine operation.

Overall, the C10 piston is designed to provide high performance, high durability and high reliability to meet the needs of diesel engines in a variety of operating environments.

Company Information

Guangzhou HDparts Co., Ltd.

Located in Guangzhou City, Guangdong Province, China

It is a company that has been in the engine parts business for about 30 years.

Production and sales integration

We have a professional technical team

And has approximately 500,000 high-quality engine parts in stock

Wholesale and retail of diesel engine parts.

We specialize in producing various diesel engine parts

Applicable to: Kubota, Yanmar, Isuzu, Mitsubishi, Komatsu, Perkins, Caterpillar, Cummins, Volvo, Doosan, Hyundai, Nissan, Hino, etc.

Cooperate with multiple countries

Our factory has a complete production line

From material processing to product shipping

Every step is arranged and operated by professional technicians

And produced according to the size required by customers.

Pistons, piston rings, cylinder liners and other engine parts are mass produced in our factory

And be responsible for arranging and supervising various production links.

Ensure high quality of products.

Meanwhile, our engine parts department offers a range of engine parts for sale

Suitable for excavators, bulldozers, forklifts, buses, and other parts.

The warehouse has half a million in inventory every year

And equipped with professional packaging management personnel and logistics

The company is committed to meeting the needs of customers around the world.

Meet and communicate with customers through global exhibitions to provide better services.

HD looks forward to cooperating with you and welcomes you to join us.

RODUCT CATEGORIES

Packaging & Shipping

Packaging material:Plastic, carton, wooden box

We get to start preparing the goods when we receive payment from you. (The goods will be sent between 48 hours to 72 hours if we have in stock. The goods will be sent before the delivery time and the sample will send to you for checking.)

FAQ

Q: What is your main products?

A:We mainly sell diesel engine parts, such as piston, piston ring, cylinder liner, crankshaft.

Q: Do you have any other products?

A:Yes, we have many other diesel engine spare parts.

Q: How to place orders?

A :The order is from your inqiuries.

-

Confrim PI (the engine model, price, quantity, packing, delivery time, shipping way, time of payment).

-

You make payment and send us receipt of payment.

-

We get to start preparing the goods when we receive payment from you. (The goods will be sent between 48 hours to 72 hours if we have in stock. The goods will be sent before the delivery time and the sample will send to you for checking.)

-

We would deliver goods after we get balance from you. The order finish when you get goods and feel satisfied.

Q: What is the MOQ?

A:We provide sample and will arrange goods as your requirements.

Q: How to make payment?

A:After you confirm PI, you can pay thruogh Alibaba Trade Assurance,Wire transfer, Western union, Paypal, Cash. (The production order can be pay 30% deposit first, after we arranged well, then you pay the balance.)

Q: Could you give guarantee ?

A:Yes, one year warranty.

Q: What kind of packing you can provide?

A:We can provide packing as your requirements or neutral packing or our own trademark packing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!